A Comprehensive Guide: Mechanical Design Engineer Interview Questions and Answers

The field of mechanical design engineering is a fascinating and essential component of numerous industries, ranging from automotive and aerospace to computer and electronic products. As a mechanical design engineer, your expertise lies in creating innovative solutions, optimizing designs for performance and efficiency, and ensuring the seamless integration of mechanical systems. When seeking a new opportunity or looking to advance in your career, the interview process is pivotal in showcasing your knowledge, skills, and suitability for the role.

THIS BLOG ARTICLE HELPS YOU PREPARE FOR SUCCESS.

This blog article provides a comprehensive guide to the most common interview questions you may encounter as a mechanical design engineer. By familiarizing yourself with these questions and crafting well-thought-out answers, you can confidently approach your interview and demonstrate your expertise to potential employers.

From foundational technical questions to those specific to industries such as automotive, aerospace, computer and electronic products, and industrial automation, this guide covers a wide range of topics. Each question is followed by a sample answer, serving as a valuable reference point as you tailor your responses to your experiences and strengths.

Interview questions in this guide explore essential areas such as design standards and regulations, weight reduction and efficiency optimization, component integration and compatibility, safety considerations, materials, manufacturing technologies, and much more. Additionally, specific questions about industry nuances are included to cater to different sectors.

Remember, while this guide provides a strong foundation, it is essential to customize your answers and bring forth your unique expertise, accomplishments, and experiences during your interview. Emphasizing your problem-solving abilities, teamwork skills, attention to detail, and adaptability will help highlight your suitability as a mechanical design engineer.

By studying these interview questions and responses, you will better understand what employers are looking for in a mechanical design engineer and be better equipped to showcase your expertise during the interview process. So, let’s dive into the guide and explore the top mechanical design engineer interview questions and answers.

Note: Remember that the answers provided in this guide are samples and should be tailored to reflect your experiences and strengths. Use them as a reference to help structure your responses, ensuring you convey your expertise and achievements effectively.

Remember, preparation is key, and with this comprehensive guide, you’re one step closer to acing your mechanical design engineer interview. Good luck!

Table of Contents

(I) Top 50 mechanical design engineer interview questions and answers

(01) Explain the design process you follow when developing a new product?

When developing a new product, I typically follow a systematic approach. It begins with understanding the requirements and objectives of the project, conducting research and analysis, creating concept designs, performing calculations and simulations, prototyping, and finally, iterating and refining the design based on feedback and testing.

(02) How do you ensure that your designs are manufacturable and cost-effective?

I collaborate closely with manufacturing and procurement teams throughout the design process to ensure manufacturability and cost-effectiveness. I consider manufacturing constraints, such as material availability, manufacturing processes, and assembly methods, from the early stages of design. Additionally, I conduct design reviews, evaluate alternative materials or components, and perform cost analysis to optimize the design for efficient production.

(03) Can you discuss your experience with CAD software and any specific tools you are proficient in?

I have extensive experience with various CAD software packages, including SolidWorks, AutoCAD, and CATIA. Using these tools, I am proficient in creating 3D models, assemblies, and detailed drawings. Additionally, I am experienced in performing simulations and analysis using software such as ANSYS or MATLAB.

(04) Describe a challenging project you worked on and how you overcame the difficulties.

One of my challenging projects involved designing a complex mechanism with strict size and weight constraints. I collaborated closely with cross-functional teams, including electrical and manufacturing engineers, to overcome the difficulties. We conducted thorough simulations and analysis, explored alternative design approaches, and performed iterative prototyping to validate and refine the design. Through effective communication and problem-solving, we successfully met the project requirements.

(05) How do you stay updated with the industry’s latest design tools and technologies?

I believe in continuous learning and professional development. I actively participate in industry conferences, workshops, and webinars to stay updated with the latest design tools and technologies. I also regularly read relevant journals, publications, and online forums to stay informed about emerging trends and advancements in mechanical design.

(06) Can you discuss your experience designing for different manufacturing processes (e.g., injection molding, machining, sheet metal)?

I have designed various manufacturing processes throughout my career, including injection molding, machining, and sheet metal fabrication. I understand the specific design considerations for each process, such as draft angles, tolerances, and material selection. By collaborating with manufacturing experts and considering these factors early in the design phase, I ensure that my designs are optimized for efficient production.

(07) How do you handle design changes or feedback from clients or stakeholders?

When receiving design changes or feedback, I approach it with an open mindset and a commitment to meeting the project objectives. I carefully evaluate the proposed changes and assess their impact on the overall design. If the changes align with the project requirements, I incorporate them into the design and iterate accordingly. Effective communication with clients and stakeholders is vital to ensure a clear understanding of their expectations and to manage any potential conflicts.

(08) Can you provide an example of when you faced conflicting design requirements and how you resolved them?

In a previous project, I encountered conflicting design requirements where achieving high performance compromised cost constraints. To resolve this conflict, I conducted a detailed analysis to identify areas where performance could be optimized without significantly increasing costs. I also collaborated with the procurement team to explore alternative materials and suppliers that could offer a balance between performance and cost. By prioritizing essential performance aspects and finding creative solutions, we achieved a design that met the client’s requirements while staying within the cost limitations.

(09) How do you ensure your designs comply with relevant industry standards and regulations?

Compliance with industry standards and regulations is a critical aspect of design engineering. I stay up-to-date with the latest standards and regulations applicable to my projects. I incorporate design features and specifications that ensure compliance from the initial stages of the design process. Additionally, I conduct thorough reviews and validation tests to verify that the design meets all the necessary requirements and safety guidelines.

(10) Describe a time when you had to work under tight deadlines. How did you manage your time and ensure project completion?

We had a tight deadline in a previous project due to an unforeseen change in the project timeline. To manage my time effectively, I divided the project into smaller milestones. I created a detailed project plan for each phase with specific deliverables and deadlines. I prioritized tasks based on their criticality and allocated resources accordingly. Additionally, I communicated with the team to ensure everyone was aware of the deadline and had the necessary support. By closely monitoring progress, making adjustments when necessary, and leveraging teamwork, we successfully completed the project within the given timeframe.

(11) How do you ensure your designs are optimized for performance and efficiency?

To optimize designs for performance and efficiency, I start by thoroughly understanding the project requirements and performance targets. I conduct simulations and analysis to evaluate different design options and select the most suitable one. I also consider material selection, component sizing, and system integration factors. I ensure that my designs meet or exceed performance expectations by leveraging my technical expertise and utilizing tools like computational fluid dynamics (CFD) or finite element analysis (FEA).

(12) Can you explain your approach to problem-solving when encountering design challenges?

When faced with design challenges, I follow a systematic problem-solving approach. I first analyze the problem and gather relevant information. Then, I brainstorm potential solutions and evaluate their feasibility. I consider technical constraints, cost implications, and impact on project timelines. I collaborate with cross-functional teams, seek input from subject matter experts, and conduct experiments or simulations when necessary. By systematically assessing options and leveraging collective knowledge, I find effective solutions to design challenges.

(13) How do you manage and prioritize multiple design projects simultaneously?

Managing multiple design projects requires effective organization and prioritization skills. I start by creating a detailed project plan for each project, outlining key milestones and deliverables. I assess the criticality and interdependencies of each project and allocate resources accordingly. I ensure that each project receives the necessary attention and progresses smoothly by maintaining clear communication with stakeholders, monitoring progress, and adapting as needed.

(14) Can you discuss your experience designing for manufacturability in high-volume production environments?

I have experience designing for manufacturability in high-volume production environments, particularly in industries such as consumer electronics. I understand the importance of designing parts that can be efficiently manufactured at scale. I consider factors like design simplification, standardized components, and automation opportunities to streamline production processes. By collaborating with manufacturing teams early in the design phase, I ensure my designs are optimized for cost-effective and reliable mass production.

(15) How do you incorporate feedback from prototype testing into your design iterations?

Prototype testing plays a crucial role in the design iteration process. When receiving feedback from prototype testing, I carefully analyze the results and identify areas for improvement. I compare the test outcomes with the initial design objectives to determine the deviations and adjust the design accordingly. I collaborate with the testing team to understand their observations and suggestions. By incorporating the lessons learned from prototype testing, I refine the design to enhance its performance, reliability, and user experience.

(16) Can you describe your experience conducting tolerance analysis and ensuring mechanical components’ proper fit and function?

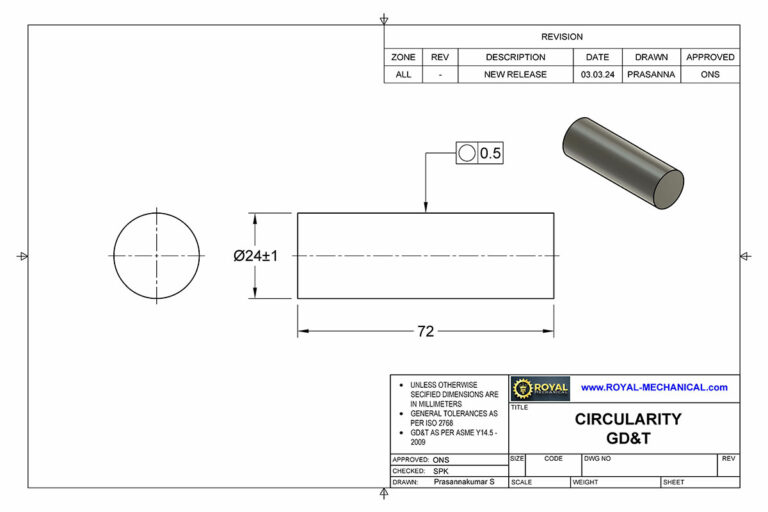

I have extensive experience conducting tolerance analysis to ensure mechanical components’ proper fit and function. I understand the importance of defining appropriate tolerances for manufacturing variations while maintaining functional requirements. I utilize tools like geometric dimensioning and tolerancing (GD&T) to specify tolerances accurately. I collaborate with manufacturing teams to understand their capabilities and implement design features that accommodate tolerances effectively. By conducting thorough analyses and considering the cumulative effects of tolerances, I ensure that components fit together as intended.

(17) How do you approach design projects with cost constraints? Give an example of how you achieved cost savings without compromising quality.

When working on design projects with cost constraints, I focus on finding opportunities for cost savings without compromising quality. For instance, we achieved cost savings by reevaluating the material selection in a previous project. We identified a more cost-effective option without compromising quality or performance by collaborating with the procurement team and exploring alternative materials that met the project requirements. Additionally, we optimized the design for efficient manufacturing processes, reducing the need for complex machining or assembly operations. By considering multiple cost-saving avenues and making informed decisions, we achieved significant cost reductions while maintaining the desired level of quality.

(18) How do you ensure your designs are reliable and durable over their expected lifecycle?

Ensuring the reliability and durability of designs is a critical aspect of my work. I consider material selection, stress analysis, and fatigue life calculations during the design phase. I conduct simulations and testing to validate the design’s performance under different operating conditions. I also analyze failure modes and implement preventive measures, such as adding redundancy or improving component robustness. By employing sound engineering principles and conducting thorough reliability assessments, I strive to create reliable and durable designs over their expected lifecycle.

(19) Can you discuss your experience collaborating with cross-functional teams, such as electrical or software engineers, for integrated product development?

Throughout my career, I have worked extensively with cross-functional teams, including electrical and software engineers, for integrated product development. I understand the importance of effective collaboration and communication between different disciplines. I actively participate in cross-functional meetings to align design requirements, ensure proper integration of mechanical components with electrical or software systems, and resolve any conflicts or dependencies. By fostering a collaborative environment and maintaining open lines of communication, I facilitate seamless integration of mechanical design with other disciplines.

(20) How do you ensure your designs are environmentally sustainable and comply with relevant regulations?

Environmental sustainability is an important consideration in modern design engineering. I prioritize the use of environmentally friendly materials and components whenever possible. I consider energy efficiency and waste reduction during the design phase, implementing features that promote sustainability. Additionally, I stay updated with environmental regulations and standards applicable to the industry, ensuring that my designs comply with them. By integrating sustainable practices and complying with regulations, I contribute to creating environmentally responsible designs.

(21) How do you approach risk assessment and mitigation in your design projects?

Risk assessment and mitigation are essential in design projects. I conduct thorough risk assessments by identifying potential failure modes, analyzing their severity and probability, and implementing appropriate mitigation strategies. This includes incorporating design features for safety and reliability, performing FMEA (Failure Mode and Effects Analysis), and conducting risk-based design reviews. By proactively addressing potential risks and implementing robust mitigation measures, I minimize the likelihood of failures and ensure the safety and performance of the final design.

(22) Can you discuss your experience designing for assembly and serviceability?

Designing for assembly and serviceability is crucial for efficient manufacturing and maintenance. I consider factors such as component accessibility, modular design, and ease of disassembly. I ensure that assembly processes are streamlined by minimizing the number of parts and optimizing their arrangement. I also incorporate features like standardized connectors and clear labeling to facilitate service and maintenance activities. By considering the entire product lifecycle, I create easy and easy to assemble and maintain designs.

(23) How do you incorporate field testing or customer feedback into your design improvements?

Feedback from field testing and customers is invaluable for design improvements. I actively gather and analyze feedback to identify areas for enhancement. I study the root cause to understand the underlying issues and implement design modifications accordingly. I collaborate with the testing team and openly communicate with customers to gain insights into their experiences and expectations. By integrating their feedback, I continuously iterate and refine the design to meet or exceed customer satisfaction.

(24) Can you discuss your experience with design for automation or robotics integration?

I have experience in designing for automation and robotics integration. I understand the importance of designing components or systems seamlessly integrating with automation or robotic processes. I consider interface compatibility, sensor placement, and programming requirements. Collaborating with automation experts ensures the design aligns with their specifications and requirements. This includes designing for precise positioning, efficient handling, and reliable interaction with automated or robotic systems.

(25) How do you ensure your designs comply with industry standards and codes?

Compliance with industry standards and codes is essential for product safety and market acceptance. I stay updated with the relevant standards and codes applicable to my design projects. I conduct thorough research and leverage design tools and resources to ensure compliance. Additionally, I collaborate with regulatory experts or third-party certification agencies to obtain necessary certifications or approvals. By incorporating industry standards from the early stages of design and conducting comprehensive compliance checks, I ensure that my designs meet all the required regulations.

(26) Can you describe when you had to work with a limited budget or resource constraints? How did you optimize your design under such conditions?

In a previous project, we had a limited budget and resource constraints. To optimize the design under these conditions, I focused on maximizing efficiency and minimizing costs without compromising quality. I conducted a detailed cost analysis and identified areas where cost savings could be achieved, such as material substitutions or component standardization. I also explored opportunities for supplier negotiations and leveraged value engineering principles to reduce costs without sacrificing functionality. By diligently managing resources and implementing cost-effective strategies, we successfully delivered a high-quality design within the given constraints.

(27) How do you approach integrating emerging technologies in your design projects, such as the Internet of Things (IoT) or additive manufacturing?

I actively embrace emerging technologies and their potential in design projects. I stay updated with the latest trends and technological advancements like IoT or additive manufacturing. I assess their applicability to my projects and evaluate their potential benefits. When integrating emerging technologies, I collaborate with experts in those fields to ensure seamless integration with mechanical design. I consider factors such as compatibility, scalability, and long-term viability. By leveraging the advantages of emerging technologies, I enhance my designs’ functionality, efficiency, and innovation.

(28) How do you approach sustainability and energy efficiency in your designs?

Sustainability and energy efficiency are important considerations in modern design engineering. I incorporate sustainable design principles by optimizing material usage, reducing waste, and promoting recyclability. I consider energy-efficient design features, such as minimizing power consumption or utilizing renewable energy sources when applicable. I also evaluate the environmental impact of the design throughout its lifecycle, including manufacturing, use, and disposal. By prioritizing sustainability and energy efficiency, I contribute to a greener and more environmentally responsible product.

(29) Can you discuss your experience designing products with user-centric design principles?

Designing products with user-centric principles is essential for creating a positive user experience. I employ user research, personas, and usability testing techniques to gain insights into user needs and preferences. I incorporate ergonomic design considerations to ensure comfort and ease of use. I also leverage user testing or focus group feedback to refine and optimize the design for intuitive operation and user satisfaction. By prioritizing user-centric design, I create products that meet the needs and expectations of the end-users.

(30) How do you approach continuous improvement and learning as a mechanical design engineer?

Continuous improvement and learning are integral to my professional development as a mechanical design engineer. I actively seek feedback and reflect on my design projects to identify areas for improvement. I regularly participate in training programs, workshops, or industry conferences to stay updated with the latest design methodologies, technologies, and best practices. I also self-study, read technical journals, and explore online resources to expand my knowledge base. I ensure my skills and expertise always evolve by embracing a growth mindset and continuously seeking new learning opportunities.

(31) How do you approach selecting materials for your designs? What factors do you consider?

When selecting materials for my designs, I consider several factors, such as mechanical properties, environmental conditions, cost, and manufacturability. I analyze the project’s requirements, including load-bearing capabilities, corrosion resistance, and thermal properties. I also evaluate the availability and cost of materials. By considering these factors, I make informed decisions to select the most suitable materials that meet the design requirements and offer optimal performance and cost-effectiveness.

(32) Can you describe when you encountered a design failure or setback? How did you handle it?

In a previous project, we encountered a design failure during testing. I immediately investigated the root cause and analyzed the failure mode. I collaborated with the testing team and other experts to understand the underlying issues. We then implemented design modifications and performed additional testing to resolve the problem. I communicated the lessons learned to the team and implemented preventive measures to avoid similar issues in the future. We overcame the setback through effective problem-solving and collaboration and delivered a successful design.

(33) How do you approach design optimization and trade-offs between design parameters?

Design optimization requires careful consideration of various design parameters and trade-offs. I start by understanding the critical performance factors and prioritizing them based on the project objectives. I utilize simulation tools and analysis techniques to explore design variations and evaluate their impact on performance, cost, and other factors. I conduct sensitivity analyses and discuss with cross-functional teams to make informed decisions. By weighing the trade-offs and finding the optimal balance, I ensure that my designs meet the project requirements while minimizing compromises.

(34) Can you discuss your experience conducting feasibility studies and design validation?

Feasibility studies and design validation are crucial steps in the design process. I have experience conducting feasibility studies to assess the technical and economic viability of design concepts. This involves evaluating manufacturing capabilities, material availability, and cost estimations. For design validation, I plan and execute tests and simulations to verify that the design meets the intended requirements and performance objectives. By conducting thorough feasibility studies and design validation activities, I ensure the design’s viability and reduce the risks associated with implementation.

(35) How do you approach cost estimation for design projects? What methodologies or tools do you use?

Cost estimation is an important aspect of design engineering. I break down the design into components and analyze their costs. I estimate material costs using historical cost data, industry benchmarks, and vendor quotes. I also consider labor costs, manufacturing processes, and any additional costs associated with outsourcing or prototyping. I leverage cost estimation tools and software, such as cost databases or parametric cost models, to facilitate accurate and reliable cost estimations. Utilizing these methodologies and tools ensures the design remains within the desired budget.

(36) Can you discuss your experience with failure analysis and corrective actions in design projects?

Failure analysis and implementing corrective actions are critical aspects of design projects. I have experience conducting failure analysis using techniques like root cause analysis, fault tree analysis, or fishbone diagrams. I collaborate with cross-functional teams and subject matter experts to identify the underlying causes of failures and implement appropriate corrective actions. This may involve design modifications, process improvements, or implementing additional quality control measures. By proactively addressing failure causes, I enhance the design’s reliability and ensure that similar issues are avoided in future iterations.

(37) How do you approach documentation and technical drawing standards in your design work?

Documentation and technical drawing standards are essential for effective communication and manufacturing. I adhere to industry-standard practices, such as ASME Y14.5, to ensure consistency and clarity in my technical drawings. I pay attention to detail, ensuring accurate dimensioning, proper tolerance specifications, and clear annotations. I also maintain organized design files and documentation, including bill of materials (BOM), design calculations, and design change logs. By following established documentation and drawing standards, I facilitate seamless collaboration with manufacturing teams and minimize errors or misinterpretations.

(38) Can you discuss your experience conducting design reviews and obtaining stakeholder feedback?

Design reviews are vital for obtaining valuable feedback and ensuring design alignment with stakeholder expectations. I have experience conducting design reviews at various stages of the design process. This involves presenting the design to stakeholders, including engineering managers, cross-functional teams, or clients. I actively encourage participation and open discussions to gather feedback on aspects like design performance, manufacturability, and adherence to project requirements. By incorporating stakeholder feedback, I enhance the design’s quality, address concerns, and ensure alignment with stakeholder expectations.

(39) How do you stay updated with the latest trends and advancements in mechanical design engineering?

Staying updated with the latest trends and advancements is crucial in mechanical design engineering. I actively engage in professional development activities, such as attending industry conferences, workshops, and seminars. I also read technical journals and research papers and follow reputable online resources. Additionally, I participate in online communities and forums where professionals share insights and discuss emerging technologies. By maintaining a continuous learning mindset and actively seeking knowledge, I stay at the forefront of the field and leverage the latest advancements in my design work.

(40) Can you provide an example of a project where you had to balance innovation with practicality in your design decisions?

In a previous project, I was tasked with designing a consumer product that required a balance between innovation and practicality. I conducted thorough market research and identified consumer needs and preferences. While exploring innovative design concepts, I also considered cost-effectiveness, manufacturability, and ease of use factors. I balanced innovation and practicality by carefully evaluating design options, leveraging user feedback, and collaborating with cross-functional teams. The final design featured unique features that set it apart from competitors while maintaining practicality and meeting customer expectations.

(41) How do you approach risk management in your design projects? Can you provide an example of a risk you encountered and how you addressed it?

Risk management is an integral part of design projects. I begin by identifying potential risks and assessing their impact and likelihood. I develop mitigation strategies to minimize risks through design modifications, redundancy, or fail-safe mechanisms. For example, in a previous project, we identified a potential risk of component failure due to excessive vibration. We conducted structural analysis, added dampening features, and tested the design’s reliability. By effectively managing risks, we ensured the safety and performance of the final product.

(42) Can you discuss your experience with Design for Manufacturing and Assembly (DFMA) principles?

I have extensive experience in applying DFMA principles to optimize designs for manufacturing and assembly processes. I consider factors such as part count reduction, design simplification, and ease of assembly. I reduce costs and lead times by leveraging standard components, minimizing customizations, and utilizing design features that facilitate efficient manufacturing and assembly. I also collaborate closely with manufacturing teams to gain insights into their capabilities and incorporate their expertise into the design process.

(43) How do you ensure compliance with regulatory and safety standards in your designs?

Compliance with regulatory and safety standards is a top priority in my designs. I conduct thorough research to identify relevant standards and regulations specific to the industry and application. I integrate compliance considerations into the design process from the early stages, ensuring that safety features, material selection, and design specifications align with the necessary requirements. I also collaborate with regulatory experts and conduct validation testing to verify compliance. By prioritizing safety and regulatory adherence, I create designs that meet the highest standards.

(44) Can you discuss your experience collaborating with suppliers and managing the supply chain during design projects?

Collaborating with suppliers and managing the supply chain is crucial for successful design projects. I engage with suppliers early in the design process to leverage their expertise in material selection, component sourcing, and manufacturing capabilities. I clearly communicate design specifications and requirements, ensuring alignment between design intent and supplier capabilities. By maintaining open lines of communication, monitoring supplier performance, and proactively addressing any issues, I ensure a smooth supply chain and timely delivery of components.

(45) How do you ensure the manufacturability and quality of your designs? Can you provide an example of a design improvement you made to enhance manufacturability?

Ensuring manufacturability and quality are essential aspects of my design process. I collaborate closely with manufacturing teams, seeking their input and considering their capabilities early on. I review the design for manufacturability (DFM) guidelines, implement design features that streamline production processes, and optimize tolerances for efficient manufacturing. For example, in a previous project, I redesigned a component to simplify its geometry, reducing the number of manufacturing steps and improving production efficiency. By proactively addressing manufacturability considerations, I enhance the overall quality and cost-effectiveness of the design.

(46) Can you discuss your experience with design verification and testing? How do you approach the validation of your designs?

Design verification and testing are critical to ensure the performance and reliability of designs. I develop comprehensive test plans based on design requirements and industry standards. I conduct validation tests, including functional, performance, and reliability, to verify that the design meets or exceeds expectations. I leverage tools like simulation software, prototypes, and test fixtures to perform testing accurately and efficiently. By analyzing test results and incorporating feedback into the design iterations, I validate the design’s performance and ensure its readiness for implementation.

(47) How do you manage project timelines and ensure timely completion of design projects?

Managing project timelines is crucial to ensure timely completion of design projects. I start by developing a detailed project plan, breaking down tasks, setting milestones, and allocating resources accordingly. I regularly monitor progress, identify potential bottlenecks, and adjust the plan. I also prioritize tasks based on criticality and dependencies, ensuring that key deliverables are met on time. By maintaining open communication with stakeholders, managing expectations, and proactively addressing any issues or delays, I ensure the project stays on track and is completed within the specified timeline.

(48) Can you discuss your experience in cost optimization and value engineering in design projects?

Cost optimization and value engineering are essential considerations in design projects. I continuously evaluate cost implications throughout the design process. I identify opportunities for cost savings by analyzing material costs, manufacturing processes, and component standardization. I also apply value engineering principles, seeking ways to improve functionality and performance while reducing costs. For example, in a previous project, we optimized cost by redesigning a component to eliminate unnecessary features and minimize material usage without compromising performance. By prioritizing cost-conscious design decisions and value engineering, I deliver designs that offer the best value for the project.

(49) How do you approach sustainability and environmental considerations in your design work?

Sustainability and environmental considerations are important aspects of design engineering. I aim to minimize the environmental impact of my designs by prioritizing energy efficiency, using sustainable materials, and promoting recyclability. I analyze the design lifecycle, considering material sourcing, manufacturing processes, and end-of-life disposal. By incorporating sustainable design principles, such as reducing waste, optimizing energy consumption, and minimizing environmental emissions, I contribute to creating environmentally conscious designs.

(50) Can you describe a situation where you had to make a design compromise due to conflicting requirements? How did you handle it?

I encountered conflicting requirements in a previous project between performance and cost constraints. To handle the situation, I engaged in thorough analysis and trade-off evaluations. I communicated with stakeholders to align priorities and understand the underlying reasons for the conflicting requirements. I explored alternative design solutions, seeking a balance between performance and cost-effectiveness. Through open dialogue and collaborative problem-solving, we reached a consensus. We made design compromises that met the project objectives within the given constraints.

(II) Top 10 mechanical design engineer interview questions and answers related to the Automotive Industry

(01) Can you discuss your experience with automotive design standards and regulations? How do you ensure compliance with industry-specific requirements?

I have extensive experience with automotive design standards and regulations, such as ISO 26262 for functional safety and FMVSS (Federal Motor Vehicle Safety Standards) for vehicle safety. I stay updated with the latest requirements by conducting thorough research and attending industry conferences. I integrate compliance considerations into the design process from the early stages, ensuring that safety features, crashworthiness, and emissions standards are met. I also collaborate with regulatory experts and conduct validation testing to verify compliance with automotive industry-specific requirements.

(02) How do you approach the design of automotive components for weight reduction and fuel efficiency?

Weight reduction and fuel efficiency are critical considerations in automotive design. I utilize design optimization techniques, such as topology optimization and lightweight material selection, to minimize component weight while maintaining structural integrity. I conduct simulations and analyses to evaluate the impact of design modifications on fuel efficiency. Additionally, I consider aerodynamics, drag reduction, and advanced powertrain technologies to improve overall vehicle fuel economy. By combining these approaches, I strive to create designs that contribute to weight reduction and increased fuel efficiency in the automotive industry.

(03) Can you discuss your experience with automotive component integration and compatibility within vehicle systems?

I have extensive experience designing automotive components and ensuring seamless integration within vehicle systems. I collaborate closely with cross-functional teams, including electrical and systems engineers, to ensure compatibility and efficient integration. I consider factors such as wiring harness routing, connector interfaces, and compatibility with vehicle control units. I also conduct compatibility tests and perform system-level simulations to validate the performance and functionality of integrated components. I create designs that meet the automotive industry’s stringent requirements by prioritizing effective collaboration and system integration.

(04) How do you approach automotive design projects focusing on occupant safety?

Occupant safety is of utmost importance in automotive design projects. I consider safety standards, such as FMVSS and Euro NCAP (European New Car Assessment Programme), from the early design stages. I conduct structural analysis, evaluate crashworthiness, and incorporate passive safety features such as seatbelt mounting points, airbag deployment zones, and energy-absorbing structures. I also collaborate with experts in the field and leverage simulation tools to conduct virtual crash tests and evaluate occupant safety performance. By prioritizing occupant safety throughout the design process, I ensure that my designs provide high protection.

(05) Can you discuss your experience with automotive powertrain design and optimization?

I have experience in automotive powertrain design and optimization. I consider engine performance, emissions control, and energy efficiency. I analyze powertrain configurations, including combustion engines, hybrid systems, or electric drivetrains, and select appropriate components to optimize power output and fuel efficiency. I also evaluate thermal management systems and conduct simulations to assess heat dissipation and cooling requirements. By leveraging my expertise in powertrain design and utilizing advanced technologies, I strive to create efficient and high-performance automotive powertrains.

(06) How do you approach automotive design projects focusing on advanced driver assistance systems (ADAS) or autonomous driving technologies?

Automotive design projects with ADAS or autonomous driving technologies require a comprehensive approach. I collaborate with experts in the field, including software engineers and sensor specialists, to integrate ADAS systems seamlessly into vehicle design. I consider factors such as sensor placement, wiring integration, and system redundancies to ensure the reliability and functionality of ADAS features. I also conduct simulations and perform validation tests to assess system performance and validate the safety and effectiveness of autonomous driving capabilities. I contribute to developing advanced automotive designs that embrace ADAS and autonomous driving technologies by prioritizing effective integration and validation.

(07) Can you discuss your experience with automotive manufacturing processes and design for assembly (DFA)?

I have extensive experience in automotive manufacturing processes and design for assembly (DFA). I collaborate closely with manufacturing engineers to understand production requirements and optimize designs for efficient assembly. I consider factors such as part consolidation, standardized fasteners, and ergonomic considerations for assembly line workers. By utilizing DFA principles, I reduce manufacturing complexity, minimize assembly time, and enhance overall production efficiency in the automotive industry.

(08) How do you approach automotive design projects with a focus on vehicle dynamics and handling performance?

I employ a multidisciplinary approach when working on automotive design projects focusing on vehicle dynamics and handling performance. I collaborate with suspension engineers, aerodynamic specialists, and tire experts to optimize vehicle dynamics. I utilize simulation tools to evaluate suspension geometry, vehicle aerodynamics, and weight distribution. By considering factors such as the center of gravity, suspension kinematics, and steering response, I strive to create designs that offer superior handling and dynamic performance in the automotive industry.

(09) Can you discuss your experience with automotive materials and manufacturing technologies, such as lightweight composites or additive manufacturing?

I have experience working with various automotive materials and manufacturing technologies, including lightweight composites and additive manufacturing. I consider the specific requirements of each project and assess the suitability of different materials. I leverage lightweight composites, such as carbon fiber reinforced polymers (CFRP), to reduce vehicle weight while maintaining structural integrity. I also explore the use of additive manufacturing for rapid prototyping and the production of complex components. By embracing innovative materials and manufacturing technologies, I contribute to advancing lightweight and efficient designs in the automotive industry.

(10) How do you approach automotive design projects focusing on noise, vibration, and harshness (NVH) control?

NVH control is crucial in automotive design to ensure a comfortable and quiet driving experience. I conduct analyses and simulations to identify potential noise and vibration sources, such as powertrain components, suspension systems, or vehicle aerodynamics. I implement design features and solutions to mitigate NVH issues, including acoustic insulation, vibration damping, and optimized component mounting. I also collaborate with experts in NVH engineering and conduct real-world testing to validate the effectiveness of design improvements. By prioritizing NVH control, I deliver automotive designs with superior comfort and reduced noise levels.

(III) Top 10 mechanical design engineer interview questions and answers related to the Aerospace Industry

(01) Can you discuss your experience with aerospace design standards and regulations? How do you ensure compliance with industry-specific requirements?

I have extensive experience with aerospace design standards and regulations, such as AS9100 for quality management and ARP4754 for aircraft systems development. I stay updated with the latest requirements by conducting thorough research and attending industry conferences. I integrate compliance considerations into the design process from the early stages, ensuring that safety, performance, and reliability requirements are met. I also collaborate with regulatory experts and conduct validation testing to verify compliance with aerospace industry-specific requirements.

(02) How do you approach the design of aerospace components for weight reduction and structural integrity?

Weight reduction and structural integrity are critical considerations in aerospace design. I utilize advanced materials, such as lightweight composites and high-strength alloys, to minimize component weight while maintaining structural integrity. I conduct finite element analysis (FEA) and stress simulations to evaluate the structural performance of components under various loading conditions. I also optimize designs through topology optimization techniques to reduce weight without compromising safety. By combining these approaches, I strive to create designs that offer optimal strength-to-weight ratios in the aerospace industry.

(03) Can you discuss your experience with aerospace component integration and compatibility within aircraft systems?

I have extensive experience designing aerospace components and ensuring their seamless integration within aircraft systems. I collaborate closely with cross-functional teams, including electrical and systems engineers, to ensure compatibility and efficient integration. I consider wiring integration, connector interfaces, and thermal management. I also conduct compatibility tests and perform system-level simulations to validate the performance and functionality of integrated components. By prioritizing effective collaboration and system integration, I create designs that meet the stringent requirements of the aerospace industry.

(04) How do you approach aerospace design projects with a focus on safety and reliability?

Safety and reliability are paramount in aerospace design projects. I consider safety standards, such as ARP4761 for aircraft safety assessment and DO-178C for software safety, from the early stages of design. I conduct thorough risk assessments, implement redundant systems, and incorporate fail-safe mechanisms to enhance safety and reliability. I also conduct reliability analyses, including failure modes and effects analysis (FMEA), to identify potential failure modes and implement preventive measures. By prioritizing safety and reliability throughout the design process, I ensure that my designs meet the stringent requirements of the aerospace industry.

(05) Can you discuss your experience with aerospace propulsion system design and optimization?

I have experience in aerospace propulsion system design and optimization. I consider engine performance, fuel efficiency, and emissions control. I analyze propulsion system configurations, including turbofan engines or rocket propulsion, and select appropriate components to optimize power output and efficiency. I also evaluate thermal management systems and conduct simulations to assess heat dissipation and cooling requirements. By leveraging my expertise in propulsion system design and utilizing advanced technologies, I strive to create efficient and high-performance aerospace propulsion systems.

(06) How do you approach aerospace design projects with a focus on aerodynamics and flight performance?

I employ a multidisciplinary approach when working on aerospace design projects focusing on aerodynamics and flight performance. I collaborate with aerodynamic specialists, structural engineers, and systems engineers to optimize the aircraft’s aerodynamic shape and performance. I utilize computational fluid dynamics (CFD) simulations to evaluate lift, drag, and stability characteristics. I also consider factors such as center of gravity, wing design, and control surfaces to enhance flight performance. By prioritizing effective aerodynamic design and considering the interaction between different aircraft systems, I contribute to developing high-performance aerospace designs that excel in aerodynamics and flight performance.

(07) Can you discuss your experience with aerospace materials and manufacturing technologies, such as advanced composites or additive manufacturing?

I have experience working with various aerospace materials and manufacturing technologies, including advanced composites and additive manufacturing. I consider the specific requirements of each project and assess the suitability of different materials for aerospace applications. I leverage advanced composites, such as carbon fiber reinforced polymers (CFRP), to achieve high strength-to-weight ratios and enhance structural performance. I also explore the use of additive manufacturing for rapid prototyping and the production of complex components with reduced weight and increased design flexibility. I contribute to developing lightweight and high-performance aerospace designs by embracing innovative materials and manufacturing technologies.

(08) How do you approach aerospace design projects with a focus on environmental sustainability and fuel efficiency?

Environmental sustainability and fuel efficiency are crucial considerations in aerospace design. I prioritize using fuel-efficient engines, advanced aerodynamic designs, and lightweight materials to reduce fuel consumption and emissions. I conduct thorough analyses and simulations to evaluate the environmental impact of the design throughout its lifecycle, including manufacturing, operation, and disposal. I also collaborate with environmental specialists and regulatory experts to ensure environmental standards and regulations compliance. By incorporating sustainable design practices and prioritizing fuel efficiency, I contribute to creating environmentally responsible aerospace designs.

(09) Can you discuss your experience with aerospace structural analysis and certification processes?

I have extensive experience in aerospace structural analysis and certification processes. I conduct finite element analysis (FEA) and stress simulations to evaluate the structural integrity of components and systems. I consider static and dynamic loads, fatigue life, and vibration characteristics. I also collaborate closely with certification authorities and regulatory bodies to ensure compliance with structural requirements and obtain necessary certifications. By adhering to rigorous structural analysis and certification processes, I create aerospace designs that meet the industry’s stringent safety and reliability standards.

(10) How do you approach aerospace design projects focusing on manufacturability and assembly efficiency?

Manufacturability and assembly efficiency are critical considerations in aerospace design projects. I collaborate closely with manufacturing engineers to understand production requirements and optimize designs for efficient manufacturing and assembly. I consider part consolidation, standardized fasteners, and modular design principles. By utilizing design for manufacturing and assembly (DFMA) principles, I reduce manufacturing complexity, minimize assembly time, and enhance overall production efficiency in the aerospace industry.

(IV) Top 10 mechanical design engineer interview questions and answers related to the Computer and Electronic Products Industry

(01) Can you discuss your experience designing computer and electronic products? What types of products have you worked on?

I have extensive experience in designing computer and electronic products. I have worked on various products, including laptops, desktop computers, servers, consumer electronics, and wearables. I have experience designing enclosures, PCBs, connectors, and cooling systems. My expertise includes considerations for product aesthetics, thermal management, and manufacturability within the computer and electronic products industry.

(02) How do you approach the design of computer and electronic products with a focus on miniaturization and compactness?

Miniaturization and compactness are crucial considerations in the design of computer and electronic products. I utilize space optimization techniques such as component integration, PCB stacking, and compact enclosure design. I also employ 3D modeling and simulation tools to ensure proper component placement, thermal management, and signal integrity. By considering miniaturization from the early stages of design, I create products that offer a compact form factor while maintaining optimal functionality and performance.

(03) Can you discuss your experience with thermal management in computer and electronic product design?

Thermal management is a critical aspect of computer and electronic product design. I have experience analyzing heat generation, conducting thermal simulations, and designing effective cooling solutions. I consider heat sinks, fans, airflow optimization, and thermal interface materials. By utilizing computational fluid dynamics (CFD) simulations and thermal analysis tools, I ensure that the product remains within safe temperature limits and maintains optimal performance.

(04) How do you approach the design of computer and electronic products for ease of assembly and serviceability?

Designing for easy assembly and serviceability is essential in computer and electronic product design. I consider factors such as modular design, standardized connectors, and easy access to components. I incorporate design features, such as snap-fit connections and tool-less disassembly, that facilitate efficient assembly processes. Additionally, I include serviceability features like accessible ports, clear labeling, and easy component replacement. By prioritizing ease of assembly and serviceability, I enhance the user experience and simplify maintenance and upgrades.

(05) Can you discuss your experience with electromagnetic compatibility (EMC) and electromagnetic interference (EMI) considerations in computer and electronic product design?

EMC and EMI considerations are critical in computer and electronic product design. I have experience designing products that comply with EMC standards, such as FCC and CE regulations. I employ proper grounding, shielding, and routing of sensitive signals to minimize electromagnetic interference. I also conduct electromagnetic simulations and testing to evaluate and optimize the product’s electromagnetic compatibility. I ensure the product operates reliably in various electromagnetic environments by addressing EMC and EMI considerations.

(06) How do you approach the design of computer and electronic products with a focus on user experience and ergonomics?

User experience and ergonomics are key considerations in computer and electronic product design. I conduct user research and usability studies to understand user needs and preferences. I incorporate ergonomic design principles to ensure comfort, ease of use, and intuitive user interfaces. I consider display visibility, button placement, and user interaction feedback. By prioritizing user experience and ergonomics, I create user-friendly, enjoyable products and meet the expectations of the end-users.

(07) Can you discuss your experience designing for high reliability and robustness in computer and electronic products?

Designing for high reliability and robustness is crucial in computer and electronic products. I consider component selection, stress analysis, and environmental testing. I incorporate design features that enhance reliability, such as redundancy, overcurrent protection, and fault tolerance mechanisms. I also conduct reliability predictions and perform accelerated life testing to validate the product’s durability and performance under different conditions. By prioritizing high reliability and robustness, I create computer and electronic products that can withstand demanding operational environments and offer long-term reliability.

(08) How do you approach the design of computer and electronic products with a focus on power efficiency and energy conservation?

Power efficiency and energy conservation are important considerations in computer and electronic product design. I conduct power analysis, optimize circuit designs, and utilize energy-saving components to minimize power consumption. I employ power management techniques such as sleep modes, dynamic voltage scaling, and power gating to optimize power usage. Additionally, I consider energy-efficient display technologies, power supply designs, and software optimization. By prioritizing power efficiency and energy conservation, I create products that offer longer battery life and reduced energy consumption.

(09) Can you discuss your experience designing computer and electronic products for manufacturability and cost-effectiveness?

Designing for manufacturability and cost-effectiveness is crucial in computer and electronic product development. I collaborate closely with manufacturing engineers to optimize the design for efficient production processes. I consider factors such as component standardization, ease of assembly, and design for automated manufacturing. I also evaluate manufacturing costs, material selection, and supply chain considerations to achieve cost-effective designs. By prioritizing manufacturability and cost-effectiveness, I streamline production processes and create efficient products to manufacture and meet cost targets.

(10) How do you approach the design of computer and electronic products with a focus on future scalability and technology integration?

Designing for future scalability and technology integration is essential in computer and electronic product design. I consider emerging technologies and industry trends to ensure that the design can accommodate future advancements. I incorporate expansion ports, flexible interfaces, and modular designs to easily integrate new features or upgrades. I also conduct technology road mapping and engage in continuous learning to stay updated with the latest developments. By prioritizing future scalability and technology integration, I create products that adapt to evolving user needs and embrace emerging technologies.

(V) Top 10 mechanical design engineer interview questions and answers related to the Machine Tool Manufacturing Industry

(01) Can you discuss your experience designing machine tools for the manufacturing industry? What types of machine tools have you worked on?

I have extensive experience in designing machine tools for the manufacturing industry. I have worked on various machine tools, including milling machines, lathes, grinding machines, CNC machining centers, and specialized equipment for specific manufacturing processes. I have expertise in designing machine components, tooling systems, motion control mechanisms, and automation features specific to machine tool applications within the manufacturing industry.

(02) How do you approach the design of machine tools with a focus on precision and accuracy?

Precision and accuracy are critical considerations in the design of machine tools. I utilize finite element analysis (FEA) and precision engineering principles to optimize structural rigidity, minimize vibrations, and ensure accurate positioning. I also consider factors such as linear motion systems, spindle design, and tooling interfaces to maintain precision and repeatability. By prioritizing precision and accuracy from the early stages of design, I create machine tools that deliver high-quality results in the manufacturing industry.

(03) Can you discuss your experience designing machine tools for high-speed machining and advanced manufacturing processes?

I have experience designing machine tools for high-speed machining and advanced manufacturing processes. I consider dynamic stability, thermal management, and cutting tool performance optimization. I optimize machine tool structures, including bases, columns, and beds, to reduce vibrations and enhance rigidity. I also integrate advanced features such as high-frequency spindles, adaptive control systems, and advanced coolant delivery mechanisms. By embracing cutting-edge technologies and design principles, I create machine tools capable of handling high-speed machining and advanced manufacturing requirements.

(04) How do you approach the design of machine tools for optimal manufacturability and ease of assembly?

Designing machine tools for optimal manufacturability and ease of assembly is crucial. I collaborate closely with manufacturing engineers to ensure the design can be efficiently produced and assembled. I consider part count reduction, standardized components, and modular designs. I also incorporate design features that facilitate efficient assembly processes, such as clear assembly instructions and accessible fasteners. By prioritizing manufacturability and ease of assembly, I streamline production processes and create efficient machine tools to manufacture and assemble.

(05) Can you discuss your experience designing machine tools for multi-axis and complex machining operations?

I have experience in designing machine tools for multi-axis and complex machining operations. I consider machine kinematics, tooling systems, and control algorithms for simultaneous multi-axis motion. I optimize the machine’s structural integrity and stability to handle complex machining forces. I also consider tool change mechanisms, workpiece positioning systems, and advanced control features for seamless operation. By leveraging my expertise in multi-axis design and advanced machining processes, I create machine tools capable of performing complex operations in the manufacturing industry.

(06) How do you approach the design of machine tools with a focus on operator safety and ergonomics?

Operator safety and ergonomics are critical considerations in machine tool design. I conduct thorough risk assessments, implement safety features such as interlocks and emergency stop mechanisms, and consider ergonomic principles for operator comfort and safety. I optimize machine enclosure designs, handle placement, and control panel layout to enhance usability and reduce operator fatigue. By prioritizing operator safety and ergonomics, I create machine tools that provide a safe and comfortable working environment for operators in the manufacturing industry.

(07) Can you discuss your experience with designing machine tools for automation and integration with manufacturing systems?

I have experience designing machine tools for automation and seamless integration with manufacturing systems. I collaborate closely with automation engineers and systems integrators to ensure compatibility and efficient integration. I consider robotic interfaces, sensor integration, and communication protocols. I design machine tools with standardized interfaces and connectivity options to enable seamless integration into automated production lines. By prioritizing automation and system integration, I create machine tools that enhance productivity and enable efficient manufacturing processes.

(08) How do you approach the design of machine tools for durability and reliability in demanding manufacturing environments?

Durability and reliability are key considerations in machine tool design for demanding manufacturing environments. I consider material selection, stress analysis, and environmental resistance. I conduct rigorous testing and validation to ensure the machine tools can withstand harsh conditions and heavy usage in manufacturing environments. I incorporate design features that enhance structural robustness, protect critical components from contamination, and optimize maintenance access. By prioritizing durability and reliability, I create machine tools that deliver consistent performance and longevity in demanding manufacturing environments.

(09) Can you discuss your experience designing machine tools for specific manufacturing industries or applications?

I have experience in designing machine tools for specific manufacturing industries or applications. For example, I have worked on machine tools for automotive part manufacturing, aerospace component machining, and medical device production. I understand the unique requirements and challenges of each industry or application and design machine tools that meet specific needs. I consider material compatibility, process requirements, and regulatory compliance to create machine tools tailored to the specific manufacturing industry or application.

(10) How do you stay updated with the latest advancements and technologies in machine tool manufacturing?

Staying updated with the latest advancements and technologies in machine tool manufacturing is essential. I actively engage in professional development activities, such as attending industry conferences, workshops, and trade shows on machine tool manufacturing. I also read technical journals and research papers and follow reputable online resources. Additionally, I participate in online communities and forums where professionals share insights and discuss emerging technologies. By maintaining a continuous learning mindset and actively seeking knowledge, I stay at the forefront of machine tool manufacturing advancements and leverage the latest technologies in my designs.

(VI) Top 10 mechanical design engineer interview questions and answers related to Industrial Automation and Robotics industry

(01) Can you discuss your experience designing mechanical systems for industrial automation and robotics applications? What types of systems have you worked on?

I have extensive experience designing mechanical systems for industrial automation and robotics applications. I have worked on various systems, including robotic manipulators, automated assembly lines, material handling systems, and robotic end-effectors. I have expertise in designing mechanisms, motion control systems, conveyors, grippers, and other components specific to the automation and robotics industry.

(02) How do you approach the design of mechanical systems for precise and repeatable motion control in industrial automation and robotics?

Precise and repeatable motion control is crucial in industrial automation and robotics. I utilize kinematic analysis, dynamic modeling, and motion profiling techniques to optimize motion control systems. I consider factors such as motor selection, gear mechanisms, feedback sensors, and control algorithms to achieve precise and smooth motion. By prioritizing precise motion control from the early design stages, I create mechanical systems that deliver accurate positioning and consistent performance in industrial automation and robotics applications.

(03) Can you discuss your experience designing robotic end-effectors and grippers for diverse industrial applications?

I have experience in designing robotic end-effectors and grippers for diverse industrial applications. I consider payload capacity, gripping force, tool-changing mechanisms, and adaptability to different workpieces. Depending on the specific application requirements, I utilize various gripping technologies, including pneumatic, electric, and vacuum-based systems. I also consider human-robot interaction aspects, safety features, and integration with control systems. By leveraging my expertise in robotic end-effector design, I create versatile and efficient gripping solutions for industrial automation and robotics.

(04) How do you approach the design of mechanical systems for seamless integration with automation controls and human-machine interfaces (HMIs)?

Seamless integration with automation controls and HMIs is essential in industrial automation and robotics. I collaborate closely with controls engineers and HMI specialists to ensure compatibility and efficient integration. I consider communication protocols, data exchange formats, and I/O interfaces. I design mechanical systems with standardized interfaces and connectivity options to enable seamless integration with automation controls and HMIs. By prioritizing integration and collaboration, I create mechanical systems that enhance productivity and enable effective human-machine interaction in industrial automation and robotics.

(05) Can you discuss your experience designing safety features and systems for industrial automation and robotics?

Safety is a top priority in industrial automation and robotics. I have experience designing safety features and systems to ensure the well-being of operators and comply with industry standards. I conduct thorough risk assessments, implement safety interlocks, and design protective enclosures for hazardous areas. I also consider emergency stop mechanisms, safety sensors, and safety-rated control systems. By prioritizing safety considerations and following industry best practices, I create mechanical systems that provide a safe working environment for operators in industrial automation and robotics applications.

(06) How do you approach the design of mechanical systems for efficient energy consumption and sustainability in industrial automation and robotics?

Efficient energy consumption and sustainability are important considerations in industrial automation and robotics. I consider factors such as motor efficiency, regenerative braking, and energy recovery mechanisms. I optimize power management systems and employ techniques such as sleep modes and power-saving algorithms. I also consider environmental aspects, such as noise reduction, emissions control, and material recyclability. By prioritizing efficient energy consumption and sustainability, I create mechanical systems that reduce operational costs and minimize environmental impact in industrial automation and robotics applications.

(07) Can you discuss your experience designing mechanical systems for collaborative robots (cobots) and human-robot collaboration?

I have experience designing mechanical systems for collaborative robots (cobots) and enabling human-robot collaboration. I consider safety-rated force sensors, soft and rounded surfaces, and collision detection mechanisms. I design mechanical systems allowing smooth and safe interaction between humans and robots. I also consider ergonomics and ease of use to enhance the user experience and facilitate efficient collaboration. By prioritizing human-robot collaboration, I create mechanical systems that enable safe and productive interactions in industrial automation and robotics.

(08) How do you approach the design of mechanical systems for scalability and adaptability in changing production environments?

Scalability and adaptability are important considerations in the design of mechanical systems for industrial automation and robotics. I design modular systems that can be easily expanded or reconfigured to accommodate changing production requirements. I consider flexible tooling systems, adjustable workpiece positioning, and adaptable control algorithms. I also integrate features that enable remote monitoring, diagnostics, and software updates for seamless system upgrades. By prioritizing scalability and adaptability, I create mechanical systems that can quickly adapt to evolving production environments in industrial automation and robotics.

(09) Can you discuss your experience designing mechanical systems for high-speed and high-throughput production in industrial automation?

I have experience designing mechanical systems for high-speed and high-throughput production in industrial automation. I optimize system dynamics, minimize inertia, and employ high-speed motion control techniques to achieve fast cycle times. I consider conveyor systems, indexing mechanisms, and parallel processing to increase production throughput. I also consider material handling strategies, such as pick-and-place and robotic transfer systems, to streamline production processes. By leveraging my expertise in high-speed production design, I create mechanical systems that maximize productivity in industrial automation.

(10) How do you stay updated with the latest advancements and technologies in industrial automation and robotics?

Staying updated with the latest advancements and technologies in industrial automation and robotics is essential. I actively engage in professional development activities, such as attending industry conferences, workshops, and trade shows on industrial automation and robotics. I also read technical journals and research papers and follow reputable online resources. Additionally, I participate in online communities and forums where professionals share insights and discuss emerging technologies. By maintaining a continuous learning mindset and actively seeking knowledge, I stay at the forefront of industrial automation and robotics advancements and leverage the latest technologies in my designs.

RELATED ARTICLES