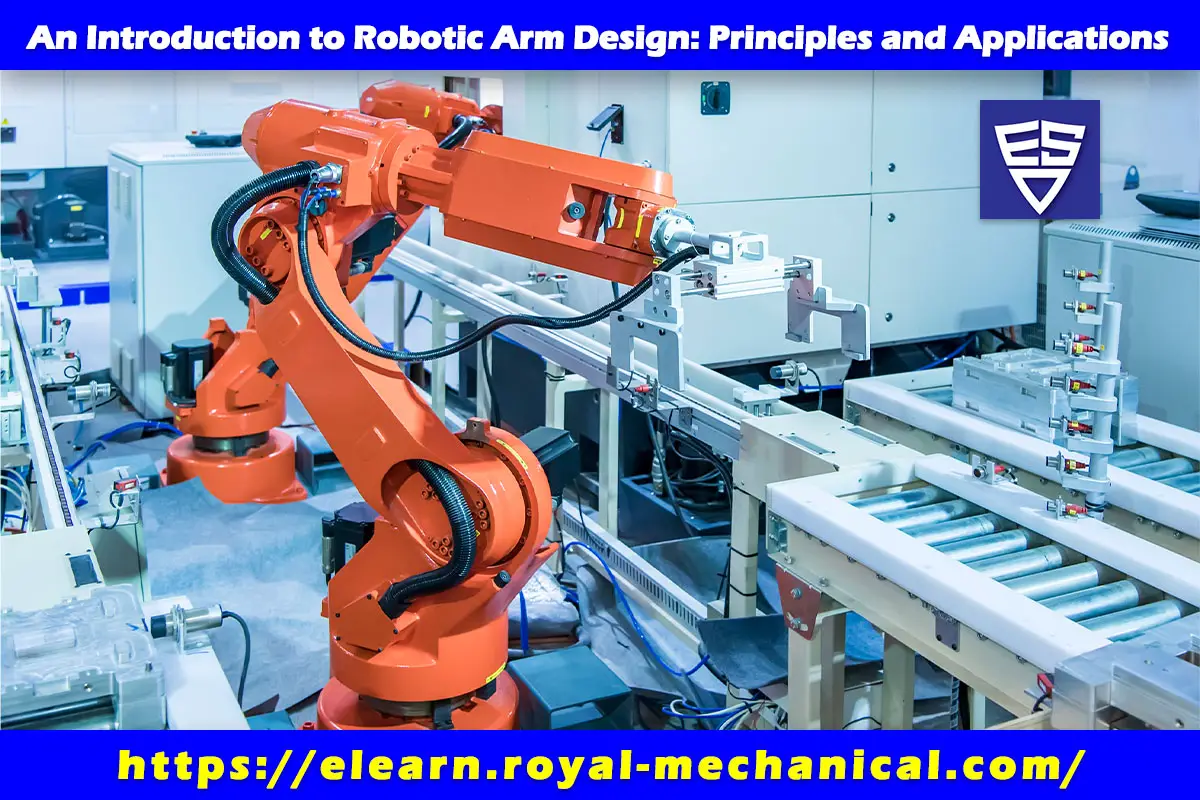

Robotic arms have become a prominent technology in various industries, revolutionizing automation and manufacturing processes. This article serves as an introductory guide to robotic arm design, exploring its fundamental principles and diverse applications. We will delve into the key components, design considerations, and the impact of robotic arms in enhancing productivity and efficiency. Whether you’re a student, engineer, or enthusiast, this article will provide valuable insights into the fascinating world of robotic arm design.

Table of Contents

01) Understanding Robotic Arm Basics:

To grasp the essence of robotic arm design, it’s essential to understand its basic components. A robotic arm typically consists of a series of interconnected segments or links, driven by actuators that enable controlled movement. The joints connecting these links define the arm’s range of motion and degrees of freedom. Common joint types include revolute (rotational), prismatic (linear), and spherical (ball-and-socket).

02) Kinematics and Motion Control:

Kinematics plays a vital role in robotic arm design. It involves studying the arm’s motion without considering the forces involved. Forward kinematics determines the position and orientation of the end effector based on the joint angles, while inverse kinematics involves calculating the joint angles required to achieve a specific end effector position. Kinematic equations, such as the Denavit-Hartenberg notation, facilitate precise mathematical representation and analysis of robotic arm motion.

03) Actuation Systems and Power Transmission:

Actuation systems provide the necessary force and torque to drive the robotic arm’s movement. Electric motors, hydraulics, and pneumatics are common actuation options, each with its own advantages and considerations. Power transmission mechanisms, such as gears, belts, or pulleys, transmit motion from the actuators to the various joints and links, ensuring accurate and efficient operation.

04) Design Considerations:

Designing a robotic arm requires careful consideration of factors like structural integrity, weight optimization, and material selection. Structural analysis techniques, such as finite element analysis (FEA), aid in evaluating stress distribution and ensuring the arm can withstand operational loads. Additionally, material selection focuses on factors such as strength, durability, and weight to strike the right balance between performance and efficiency.

05) End Effectors and Grippers:

The end effector is the robotic arm’s “hand” and performs specific tasks. Grippers, tooling systems, or specialized attachments can be integrated as end effectors to facilitate grasping, manipulating objects, or performing complex operations. The choice of end effector depends on the application requirements, ranging from simple mechanical grippers to advanced sensor-equipped systems for delicate handling or precise assembly.

06) Applications of Robotic Arms:

Robotic arms have found extensive applications across various industries. In manufacturing, they streamline assembly lines, increase production efficiency, and enhance product quality. They are also used in hazardous environments, such as nuclear facilities or chemical plants, where human access is limited. Robotic arms play a crucial role in medical procedures, including surgery and rehabilitation, enabling precise and minimally invasive interventions. Furthermore, they are deployed in aerospace, agriculture, logistics, and countless other sectors to automate processes and improve overall productivity.

Conclusion:

Robotic arm design is a dynamic field with immense potential and diverse applications. By understanding the principles behind robotic arm design, one can unlock its capabilities to revolutionize industries and push the boundaries of automation. This introduction provides a solid foundation for further exploration into the intricate world of robotic arm design and its limitless possibilities.

In summary, robotic arm design encompasses key elements such as kinematics, actuation systems, structural considerations, end effectors, and diverse applications. By comprehending these principles, engineers and