Introduction

In today’s fast-paced design and engineering world, Computer-Aided Design (CAD) has become an indispensable tool. Whether you’re an architect, engineer, or product designer, CAD software has revolutionized how we create and visualize designs. This comprehensive guide aims to demystify CAD and provide a solid understanding of its principles, applications, and benefits. From the basics of CAD software to advanced techniques and industry trends, this article covers everything you need to know about Computer-Aided Design.

Table of Contents

I. What is Computer-Aided Design?

Computer-Aided Design, commonly known as CAD, uses computer software to create, modify, analyze, and optimize designs. It has replaced traditional manual drafting methods, enabling designers to work faster, more accurately, and flexibly. CAD systems offer various tools and features, allowing designers to create 2D and 3D models, generate precise measurements, simulate real-world conditions, and produce detailed technical documentation.

II. Evolution and History of CAD

CAD has a rich history that dates back several decades. The early CAD systems emerged in the 1960s, primarily used for aerospace and automotive design. Over time, computer hardware and software advancements led to the development of more sophisticated CAD tools. The introduction of 3D modeling capabilities revolutionized the industry, giving designers a realistic representation of their designs. Today, CAD has expanded its reach across various fields, including architecture, engineering, manufacturing, and entertainment.

III. Benefits of CAD

CAD offers numerous benefits that have transformed the design process. Firstly, it enhances productivity by allowing designers to iterate and modify designs quickly. Changes can be made effortlessly without the need for redrawing entire blueprints. CAD software facilitates collaboration by enabling multiple designers to work simultaneously on the same project. It improves accuracy, reducing errors and ensuring precise measurements. Additionally, CAD provides visualization capabilities, allowing designers to create realistic renderings and walkthroughs of their designs. This aids in effective communication with clients, stakeholders, and production teams.

IV. CAD Software and Tools

A wide range of CAD software is available in the market, each with its own features and capabilities. Some popular CAD software options include AutoCAD, SolidWorks, CATIA, Fusion 360, and Revit. These tools offer powerful modeling capabilities, extensive libraries of predefined components, parametric design options, and integration with other software systems. CAD software often includes additional features like simulation, analysis, and rendering, enabling designers to effectively validate and showcase their designs.

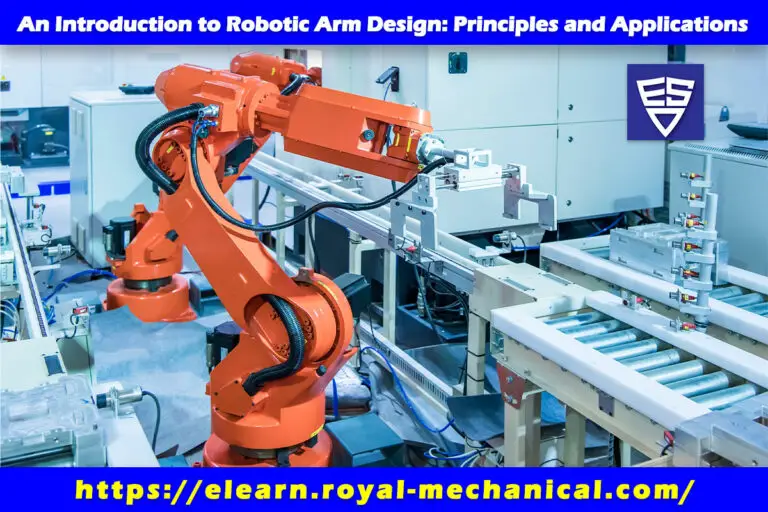

V. CAD Applications in Different Industries

CAD finds applications in various industries crucial in design and development processes. In architecture, CAD is used to create detailed floor plans, elevations, and 3D models of buildings. In engineering, CAD aids in the design of mechanical components, electrical systems, and structural elements. The manufacturing industry relies on CAD to create product prototypes, optimize production processes, and generate manufacturing instructions. CAD is also widely utilized in the automotive, aerospace, and consumer product industries, among others, for designing and simulating complex systems.

VI. Trends and Future of CAD

As technology continues to evolve, CAD is constantly adapting to meet the changing needs of designers and engineers. Some notable trends include the integration of CAD with other software systems, such as computer-aided manufacturing (CAM) and product lifecycle management (PLM). The rise of cloud-based CAD platforms enables seamless collaboration and access to designs from any location. Additionally, virtual and augmented reality advancements are transforming how designers visualize and interact with CAD models, providing immersive experiences.

VII. Top CAD Software in the Industry

Regarding CAD software, numerous options are available in the market, each with its own strengths and specialties. Here are the top CAD software programs widely used in the industry:

1) AutoCAD:

Developed by Autodesk, AutoCAD is a widely recognized CAD software that offers comprehensive 2D drafting and 3D modeling tools. It is extensively used in architecture, engineering, and construction industries for its versatility and industry-standard compatibility.

2) SolidWorks:

SolidWorks is renowned for its user-friendly interface and powerful 3D modeling capabilities. It is a popular mechanical design choice, offering parametric modeling, assembly design, and simulation features.

3) CATIA:

Developed by Dassault Systèmes, CATIA is a leading CAD software, particularly in the aerospace and automotive industries. It provides advanced surface modeling, complex assembly design, and analysis capabilities, making it suitable for large, intricate projects.

4) Fusion 360:

Fusion 360, offered by Autodesk, is a cloud-based CAD software that combines 3D modeling, simulation, and collaboration tools in a single platform. It is known for its affordability and accessibility, making it a popular choice for startups, small businesses, and hobbyists.

5) Siemens NX:

Siemens NX is a comprehensive CAD/CAM/CAE software suite that supports product design, manufacturing, and simulation. It offers advanced features for multi-disciplinary design and integration with other Siemens PLM (Product Lifecycle Management) solutions.

6) PTC Creo:

PTC Creo is a versatile CAD software with parametric modeling, analysis, and manufacturing capabilities. It offers a wide range of tools for 3D design. It is widely used in the automotive, aerospace, and consumer products industries.

7) Solid Edge

Solid Edge, developed by Siemens, is a powerful cad software known for its ease of use and comprehensive set of tools for mechanical design. It provides parametric modeling, assembly design, simulation, and rendering features. Solid Edge’s user-friendly interface makes it popular for designers of all skill levels.

8) DraftSight

DraftSight, developed by Dassault Systèmes, a 2D cad software offering a cost-effective mechanical design solution. It provides familiar drafting tools and a user-friendly interface, making it suitable for small businesses and individuals working primarily with 2D designs.

9) Autodesk Inventor

Autodesk Inventor, another powerful cad software from Autodesk. Inventor is specifically designed for mechanical design and engineering. It offers advanced tools for 3D parametric modeling, assembly design, simulation, and rendering. Inventor streamlines the entire design process with its integrated workflow and collaboration capabilities.

10) Revit:

Revit, also developed by Autodesk, is a prominent BIM (Building Information Modeling) software. It specializes in creating intelligent 3D models of buildings, incorporating data for accurate documentation and collaboration in the architecture, engineering, and construction industries.

11) Rhino:

Rhino, or Rhinoceros, is a popular 3D modeling and industrial design CAD software. It offers flexibility in modeling complex shapes and is widely used in architecture, jewelry design, and product development.

12) SketchUp:

SketchUp is a user-friendly CAD software known for its intuitive interface and ease of use. Architects, interior designers, and hobbyists often favor it for its quick and efficient 3D modeling capabilities.

13) FreeCAD:

As the name suggests, FreeCAD is an open-source CAD software that is free to use. It provides parametric modeling features and is suitable for various design disciplines, including mechanical engineering and architecture.

These CAD software programs offer various features, capabilities, and industrial applications. When selecting the right software, you must consider specific requirements, project complexity, and personal preferences to ensure the best fit for your design needs.

VIII. Conclusion

Computer-Aided Design has revolutionized the way we approach design and engineering. Its ability to streamline the design process, enhance collaboration, and produce accurate representations has made it an indispensable tool in various industries. By understanding CAD’s principles, benefits, and applications, designers can leverage its power to bring their creative visions to life. Stay updated with the latest advancements and trends in CAD as it continues to evolve and shape the future of design. Embrace the power of CAD, and unlock your true potential as a designer or engineer.

IX. FAQs: Computer-Aided Design (CAD)

What is CAD, and what does it stand for?

CAD stands for Computer-Aided Design. It uses computer software to create, modify, analyze, and optimize designs.

How does CAD software benefit designers and engineers?

CAD software offers numerous benefits, including increased productivity, faster design iterations, improved accuracy, enhanced visualization, better collaboration, and seamless integration with other design and manufacturing processes.

What are the main differences between 2D CAD and 3D CAD?

2D CAD is primarily used for creating 2D technical drawings. At the same time, 3D CAD allows designers to create realistic 3D models that represent physical objects more accurately.

Can CAD software be used in different industries?

Yes, CAD software is utilized in various industries such as architecture, engineering, manufacturing, automotive, aerospace, product design, etc.

Which industries rely heavily on CAD for their design processes?

Industries such as architecture, engineering, construction, manufacturing, automotive, aerospace, and consumer products heavily rely on CAD for their design and development processes.

What are some popular CAD software programs available in the market?

Popular CAD software programs include AutoCAD, SolidWorks, CATIA, Fusion 360, Revit, Siemens NX, PTC Creo, Rhino, SketchUp, and FreeCAD.

Is CAD software suitable for small businesses and individual designers?

Yes, CAD software is suitable for small businesses and individual designers. There are free and affordable CAD software options to cater to different budgets and usage requirements.

Can CAD software handle complex design projects?

Yes, CAD software is capable of handling complex design projects. It provides advanced modeling, simulation, analysis, and documentation tools to support complex design requirements.

How does CAD software facilitate collaboration among design teams?

CAD software enables multiple designers to work on the same project simultaneously. It provides features for version control, file sharing, real-time collaboration, and easy communication, enhancing teamwork and efficiency.

What are the key features to consider when choosing CAD software?

Key features to consider include ease of use, modeling capabilities (2D and 3D), compatibility with file formats, available tools for analysis and simulation, integration with other software systems, and customer support.

Can CAD software integrate with other software systems?

Many CAD software programs integrate with other software systems, such as computer-aided manufacturing (CAM), product lifecycle management (PLM), simulation software, and data management systems, to streamline the design and manufacturing processes.

Are there any free or open-source CAD software options available?

Free and open-source CAD software options are available, such as FreeCAD and LibreCAD, which provide basic to intermediate CAD functionality without significant financial investment.

Can CAD software help with the analysis and simulation of designs?

Yes, CAD software often includes tools for analysis and simulation, enabling designers to evaluate factors such as structural integrity, fluid dynamics, thermal behavior, and ergonomic considerations.

What are the advantages of using parametric CAD modeling?

Parametric CAD modeling allows designers to create designs driven by parameters or variables. It provides flexibility for design modifications, automatic updates across related components, and easier design iterations.

How does CAD software assist in creating accurate technical documentation?

CAD software offers tools for generating precise technical drawings, annotations, dimensions, and bills of materials, ensuring accurate documentation for manufacturing and construction processes.

What are the trends and future developments in CAD technology?

Current trends include cloud-based CAD platforms, integration with emerging technologies like virtual and augmented reality, and increased focus on generative design and artificial intelligence-driven capabilities.

Are there any specific CAD certifications or training programs available?

Yes, various CAD certifications and training programs are available, offered by software vendors, educational institutions, and professional organizations, which can enhance proficiency and demonstrate expertise in CAD software usage.

How does CAD software improve productivity and reduce design iterations?

CAD software offers features like parametric modeling, design automation, and easy modification tools, allowing designers to create and modify designs quickly, reducing the time required for design iterations.

Can CAD software assist in creating photorealistic renderings of designs?

Yes, many CAD software programs provide rendering capabilities that enable designers to create photorealistic images and visualizations of their designs, helping stakeholders visualize the final product.

What are some tips for beginners to get started with CAD software?

For beginners, it’s essential to start with tutorials and basic training resources provided by the software vendor. Practicing simple projects, seeking guidance from experienced users, and exploring online forums and communities can also help you learn CAD software effectively.

Featured Article:

Related Articles: